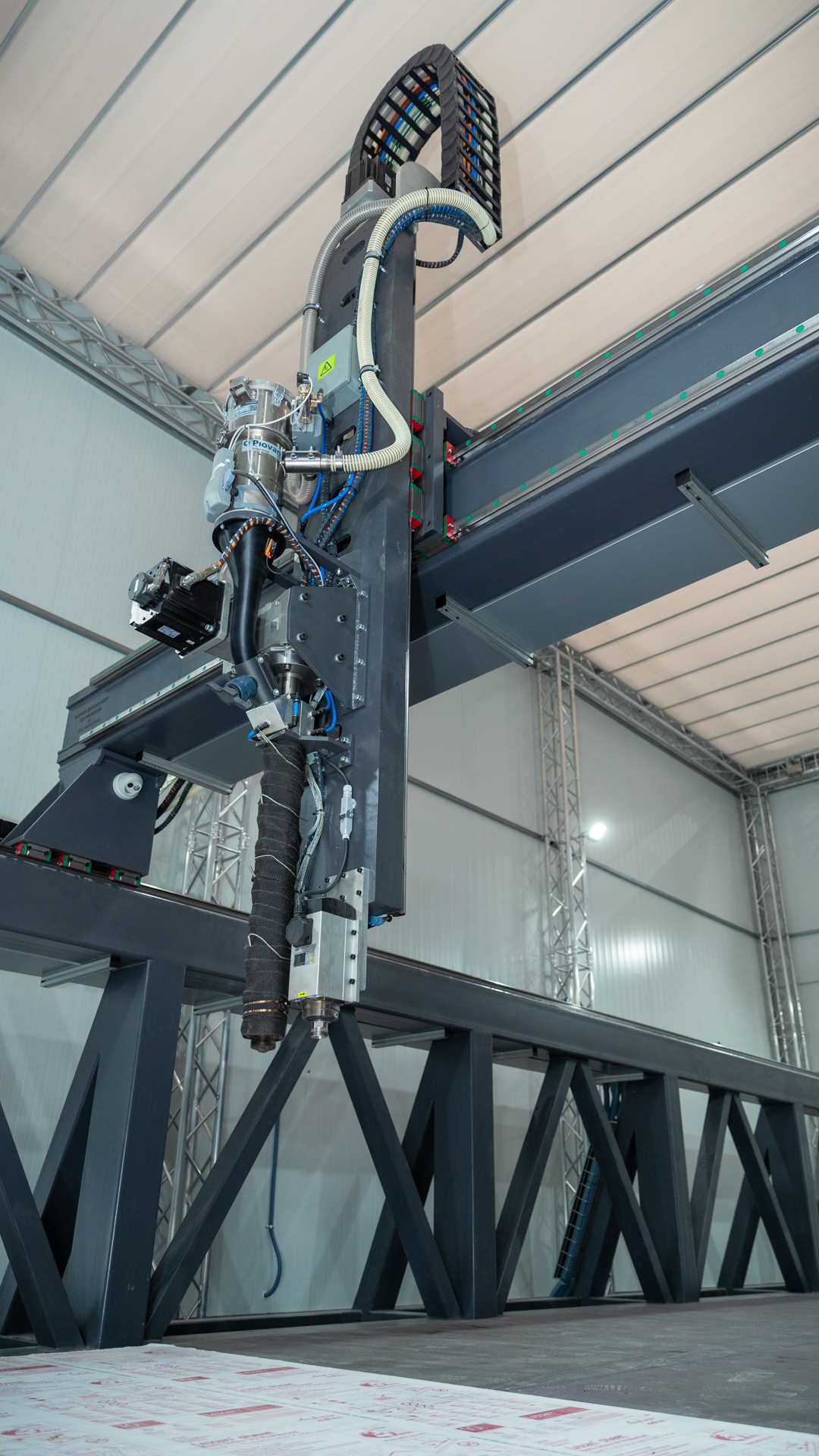

We have three machining centers.

The possible dimensions to be machined are:

CNC I

X=23.8m Y=6.5m Z=3.2m | Precisión +/- 0.5mm

CNC II

X=26m Y=8.5m Z=4.0m | Precisión +/- 0.5mm

CNC III

X=6m Y=2.2m Z=0.8m | Precisión +/- 0.5mm

Oriented to obtain the maximum satisfaction and loyalty of our clients over time, our work is based on perseverance to achieve the established objectives and a result proportional to our effort.

Sinergia Racing Group (SRG) is a multidisciplinary engineering company that was born in 2001 linked to nautical competition construction.

Subsequently, it derives its activity to the manufacture of models, numerical control molds and the manufacture of parts and prototypes in composite materials.

We work to continue obtaining national and international recognition as manufacturers of models and molds and thus become a leading company in the composite materials sector and we base our success on attention to detail and continuous improvement.

Our daily task consists in the development and production of high quality models and molds by using the best materials and processes to guarantee the achievement of objectives based on attention to detail.

With more than 20 years of experience in the sector, the SRG team has evolved from a vertical structure to the creation of teams capable of carrying out their project in an autonomous way.

Providing our customers with engineering solutions through our knowledge of composite materials and materials engineering, together with our process competencies.

to plan with a certain order and methodology the idea provided by the client in order to converge and start working on the Desired Design.

If you have a preconceived idea, but you don’t know how to materialize it, we can help you and makeit come true.

The success of adapting the correct mold to a specific part depends to a large extent on the requirements being found out and established. Two of the most important requirements are temperature and vacuum.

The mold is closely related to the materials with which the piece is to be manufactured.

The molds are manufactured from CNC machines, and there may be a limitation due to the size of the machine, geometry of the piece or the size of the machine head.

There is a certain chemical incompatibility of certain matrices such as that of some release agents with the temperature or of some monomers, etc.

Establish dimensional and other tolerances; How are they measured, when…

Making molds for pure RTM is not the same as for infusion. This is related to the cost: few clients do not give importance to this issue.

Our mission is to provide our customers with engineering solutions through our knowledge of composite materials and materials engineering, together with our process competencies.

The possible dimensions to be machined are:

X=23.8m Y=6.5m Z=3.2m | Precisión +/- 0.5mm

X=26m Y=8.5m Z=4.0m | Precisión +/- 0.5mm

X=6m Y=2.2m Z=0.8m | Precisión +/- 0.5mm

5 stars review on google

Vestas

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Navantia

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Aerotecnic

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Specialist manufacturers of plugs, moulds & prototypes for composites.

©2023 Sinergia Racing Group S.L.U

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.